The beginning

Introduction

Jack Tramiel was born in Poland. He survived the concentration camps of World War II. In the year 1948 he emigrated to the United States. He joined the US army and became a typewriter repair man. In 1952 Jack left the army to set up his own company. It was just a little store that would repair typewriters and he didn't make that much money.

Jack Tramiel was born in Poland. He survived the concentration camps of World War II. In the year 1948 he emigrated to the United States. He joined the US army and became a typewriter repair man. In 1952 Jack left the army to set up his own company. It was just a little store that would repair typewriters and he didn't make that much money.In 1955 he got a contract to assemble typewriter for a Czechoslovakian company. In Canada he met C. Powell Morgan who wanted to put money into the new company. With this deal Jack founded the company "COMMODORE". A few years later in 1962 Commodore went public. In 1965 there was trouble. The financial company of C. Powell Morgan went bankrupt and Commodore was in financial trouble. The next year a new money man was found by the name of Irving Gould.

In the sixties Commodore starting to make mechanical calculators and later electronic calculators. The first computers came after Commodore bought the company MOS in 1976. With this deal Commodore could make it's own chips for the calculators and get in the new world of computers. [77]

The calculators

After the typewriters came the mechanical calculators or "adders". Then Commodore started to make electronic calculators. The calculators were assembled with components from other companies. The chips that were needed came from Texas Instruments. Business was good and Commodore produced more than 25 different models. The company Texas Instruments was only making the chips so it was not a competitor for Commodore. But things changed and Texas Instruments started to produce it's own calculators. The price of the complete Texas Instruments calculator was almost the same as the price that Commodore had to pay for the chips. This put Commodore in a difficult spot. But Jack Tramiel was a very clever business man. He found out that a relative new company (MOS) also could make chips for his calculators. So he placed a large order for chips at MOS. Jack was stalling payments to MOS to get MOS into financial trouble. And after a while he took over the company MOS for a very cheap price. Jack was now owner of a chip making company and was an independent manufacturer.

After the typewriters came the mechanical calculators or "adders". Then Commodore started to make electronic calculators. The calculators were assembled with components from other companies. The chips that were needed came from Texas Instruments. Business was good and Commodore produced more than 25 different models. The company Texas Instruments was only making the chips so it was not a competitor for Commodore. But things changed and Texas Instruments started to produce it's own calculators. The price of the complete Texas Instruments calculator was almost the same as the price that Commodore had to pay for the chips. This put Commodore in a difficult spot. But Jack Tramiel was a very clever business man. He found out that a relative new company (MOS) also could make chips for his calculators. So he placed a large order for chips at MOS. Jack was stalling payments to MOS to get MOS into financial trouble. And after a while he took over the company MOS for a very cheap price. Jack was now owner of a chip making company and was an independent manufacturer.On the photo the 776M electronic calculator. [78]

The KIM-1

The KIM-1 was Commodore first real computer. But the KIM-1 was designed by the Company MOS. MOS was founded in 1974 by 8 former employees of Motorola. Two of those people were Bill Mensch and Chuck Peddle. The new company was called MOS Technology and it started development on the 6501 chip. This was a microprocessor that was pin compatible with the 6800 chip from Motorola. The internal design was different but Motorola sewed MOS for copying there design. MOS and Motorola settled this disagreement and the 6501 was dropped. MOS went on with designing there new processor. This was the 6502. The 6502 is one of the most important microprocessors ever made. The driving force behind the development of the 6502 was Chuck Peddle. Now the 6502 was born MOS designed a complete computer that used the 6502. The KIM-1 was born. But in the same year the company was taken over by Jack Tarmiel's company Commodore. There are KIM-1's with MOS on the motherboard but the later had the Commodore and the MOS name on the motherboard.

The KIM-1 was Commodore first real computer. But the KIM-1 was designed by the Company MOS. MOS was founded in 1974 by 8 former employees of Motorola. Two of those people were Bill Mensch and Chuck Peddle. The new company was called MOS Technology and it started development on the 6501 chip. This was a microprocessor that was pin compatible with the 6800 chip from Motorola. The internal design was different but Motorola sewed MOS for copying there design. MOS and Motorola settled this disagreement and the 6501 was dropped. MOS went on with designing there new processor. This was the 6502. The 6502 is one of the most important microprocessors ever made. The driving force behind the development of the 6502 was Chuck Peddle. Now the 6502 was born MOS designed a complete computer that used the 6502. The KIM-1 was born. But in the same year the company was taken over by Jack Tarmiel's company Commodore. There are KIM-1's with MOS on the motherboard but the later had the Commodore and the MOS name on the motherboard.The components:

The KIM-1 is a real computer but it's nothing compared with a modern PC. The KIM has the following major parts. The 6502 microprocessor, Two 6530 I/O chips, 1 kbyte RAM, 2 kbyte ROM, a 6 digit 7-segment LED display. The rest of the component are simple logic components.The 6502 technical specifications:

Data bus: 8 bitsAddress bus: 16 bits

Interrupts: IRQ, NMI, RDY

Speed: 1 MHz

Instructions: 151

The 6502 is microprocessor. Inside a microprocessor all kinds of binary manipulations can be made on data. To get data in and out of the microprocessor a data bus is needed. The data bus of the 6502 is 8 bits wide that means that it has 8 pins that can connect with memory outside the 6502. The 6502 works like all other processors with the binary system. That means there are only 2 possibilities on or off. This will be shown as a 0 or a 1. This is called a bit. If you got a 8 bit wide data bus then the possibilities are 00000000 to 11111111. A value of 8 bit wide is called a byte. In the normal decimal system that is 0 to 255. All processing is limited to the numbers 0 to 255. If you need bigger numbers you will have to chop the big number into little parts.

But there is also something needed to point at the location of the data. This is called a address bus. On the 6502 the address bus of the 6502 is 16 bits wide. With 16 bits you can make numbers between 00000000 00000000 and 11111111 11111111. Or in decimals between 0 and 65536. The 6502 can address 64 kbyte of memory. Keeping in mind that the KIM-1 has only 3 kbytes of RAM / ROM memory the address bus is big enough.

Besides the Data and Address bus the 6502 has also interrupts. An interrupt is a stop-sign. The processor can be halted with an interrupt.

The system speed of the KIM-1 is 1 MHz. This means that there are 1 million actions per second that are processed. So the 6502 processor can do 1.000.000 action every second. The fasted instruction takes only 2 actions but the slowest instruction takes 7.

The 6502 has instructions. The number of instructions is 151 but there are in theory 255 instruction possible. Programmers found extra instructions by experimenting. But these are actually defects that are build into the chips and are not real instructions. There are instructions that only move data like LDA (Load the accumulator with a value) but there are also instructions that will calculate data like ADD (ADD a value to the accumulator) Also there are instructions the manipulate a value like ROR which shifts the bits a place to the right.

The 6530 technical specifications:

Data bus: 8 bitsI/O: 2 x 8 bits (bi-directional)

Timer: programmable

RAM: 64 byte

ROM: 1 kbyte

The two 6530 are the connection with the outside world. The keyboard is read with these chips. The display is also driven by the 6530's. To save your programs there is also a connection for a cassette recorder. And even a teletype connection is available. Almost all of the IO are also available on the edge connectors.

Because the 6530 has it's own ROM there are different types of 6530. MOS have produced different 6530 for specific tasks or other companies.

RAM / ROM:

Nowadays 1 kbyte of RAM is a joke but in 1976 this was huge. RAM is used to store your own program code. RAM can be written and read. RAM stands for Random Access Memory. There is also 2 kbyte of ROM. In this ROM is a program that runs the KIM-1. It takes care of reading the keyboard does the display and the save and load commands. Also it has a machine language assembler to help you to type in your machine language program. ROM can only be read. ROM stands for Read Only Memory. The ROM keeps it's program even when the power supply is disconnected. RAM loses all it's data when this happens.Keyboard / Display:

To make a complete computer you will need a way to interact with it. Input from the user is done via a simple keyboard with the hexadecimal numbers from 0 to F, a reset button, some keys for programming and a on/off switch.The display is made up from six 7-segments LED displays. Because the microprocessor can access the individual segments on each display via the 6530's you can display more than 0-9.

On the photo the KIM-1. This is a revision-G from November 1978 [79]

The Chessmate

When the KIM-1 came out people started to write software for it. One of those people was Peter Peter Jennings who worked for Commodore. He wrote Microchess for the KIM-1 and later also for the C64/128. Commodore decided to make a ready to use version of Microchess. This is the Chessmate. If you look at the design it looks a lot like the KIM-1 but not everything is the same. Besides the differences on the hardware side the Chessmate was put in a nice cabinet and a (external) power supply was included.

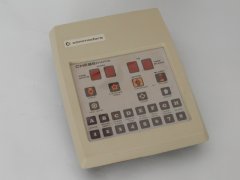

When the KIM-1 came out people started to write software for it. One of those people was Peter Peter Jennings who worked for Commodore. He wrote Microchess for the KIM-1 and later also for the C64/128. Commodore decided to make a ready to use version of Microchess. This is the Chessmate. If you look at the design it looks a lot like the KIM-1 but not everything is the same. Besides the differences on the hardware side the Chessmate was put in a nice cabinet and a (external) power supply was included.The 6504:

The microprocessor is a 6504 instead of a 6502. The main difference is that it's only a 28 pin chip (6502 is a 40 pin chip). The 6504 can only address 8 kbyte of memory has only one interrupt but it has a build in clock. The 6504 runs on a clock frequency of 1 MHz.Besides the microprocessor there is also a RIOT chip the 6530 which handles the keyboard and the 4 7-segments LED display.

The 6530: see also the KIM-1.

The 6530 reads the keyboard and the drives the four 7-segments LED display. It also controls four LEDs on the panel and controls a small beeper.RAM / ROM:

The Chessmate has only 256 bytes of RAM. The ROM is filled with the program Microchess 1.5 and is 4 kbyte in size. The 6530 has another 64 bytes of RAM and 1 kbyte of ROM but they are not used.Keyboard / Display:

For the interaction with the user the Chessmate has a membrane style keyboard like on the MAX-machine. The main display has four 7-segments LED displays. There are 4 more LEDs that give you information on the status of the chess game.On the photo the Chessmate. [80]

The 2000K

Before "real" computers hit the consumer market a lot of companies sold a "pong" game console. Commodore had bought MOS Technologies and MOS also made a pong chip. In the 2000K Commodore used the 7600 (NTSC) and the 7601 (PAL) chip. The 2000K can be operated with and external power supply or on batteries. The 2000k hit the shops around 1976/77.

Before "real" computers hit the consumer market a lot of companies sold a "pong" game console. Commodore had bought MOS Technologies and MOS also made a pong chip. In the 2000K Commodore used the 7600 (NTSC) and the 7601 (PAL) chip. The 2000K can be operated with and external power supply or on batteries. The 2000k hit the shops around 1976/77.Most pongs were build around one chip. The 7600/1 was a simple microprocessor that could read the build in ROM to create the game. The TV display was also handled by the 7600/1. The display has four colors. The console even had sound. The beep came out of a build in speaker.

Keyboard / Controllers

The 2000K has 4 controllers that are comparable with a paddle like on the VIC-20 and the C64/128 but do not have a fire button. Two of the controllers are connected to the 2000K and two more can be connected via a connector. An optional rifle can be attach to shoot at the screen.The machine has the following switches: On/Off, 2 or 4 players, Auto serve on/off, expert or amateur, Reset, Manual serve. The center switch controls the game: Tennis, Football, Squash and Target.

On the photo the 2000K pong. This unit is from August 1977. [81]

The 3000H

The 3000H is very similar to the 2000K. The main difference is that the controllers use slider. One of the controllers is build into the unit. The second controller is connected to the unit via a cable. The other two connect with a connector. The connectors for the controllers are different to the 2000K.

The 3000H is very similar to the 2000K. The main difference is that the controllers use slider. One of the controllers is build into the unit. The second controller is connected to the unit via a cable. The other two connect with a connector. The connectors for the controllers are different to the 2000K.On the photo the 3000H pong. [82]

Update: 2011-06-24 19:22:42